Civil Engineering Student Canoe Design Competition

The Annual Concrete Canoe Design Competition for all US Civil Engineering Students is sponsored by the American Society for Civil Engineers. Information on the competition can be found on the ASCE Website .

Concrete Canoe Design Tests Civil Engineering Skill Sets

Students are required to create a canoe that can not only float but be raced by team members in the water. Each team must also prepare a full design report that provides structural analysis as well as hydrostatics calculations and stability analysis with crew in place. As a result each Concrete Canoe design team must obtain design and analysis software that allows them to meet the design competition requirements as well as be sure that their proposed design will be safe to paddle to victory with a crew of four aboard. Knowledge of the actual waterline and remaining freeboard above the water that will afford protection and prevent water coming aboard in wind and wild paddling battles!

Courtesy ASCE Website

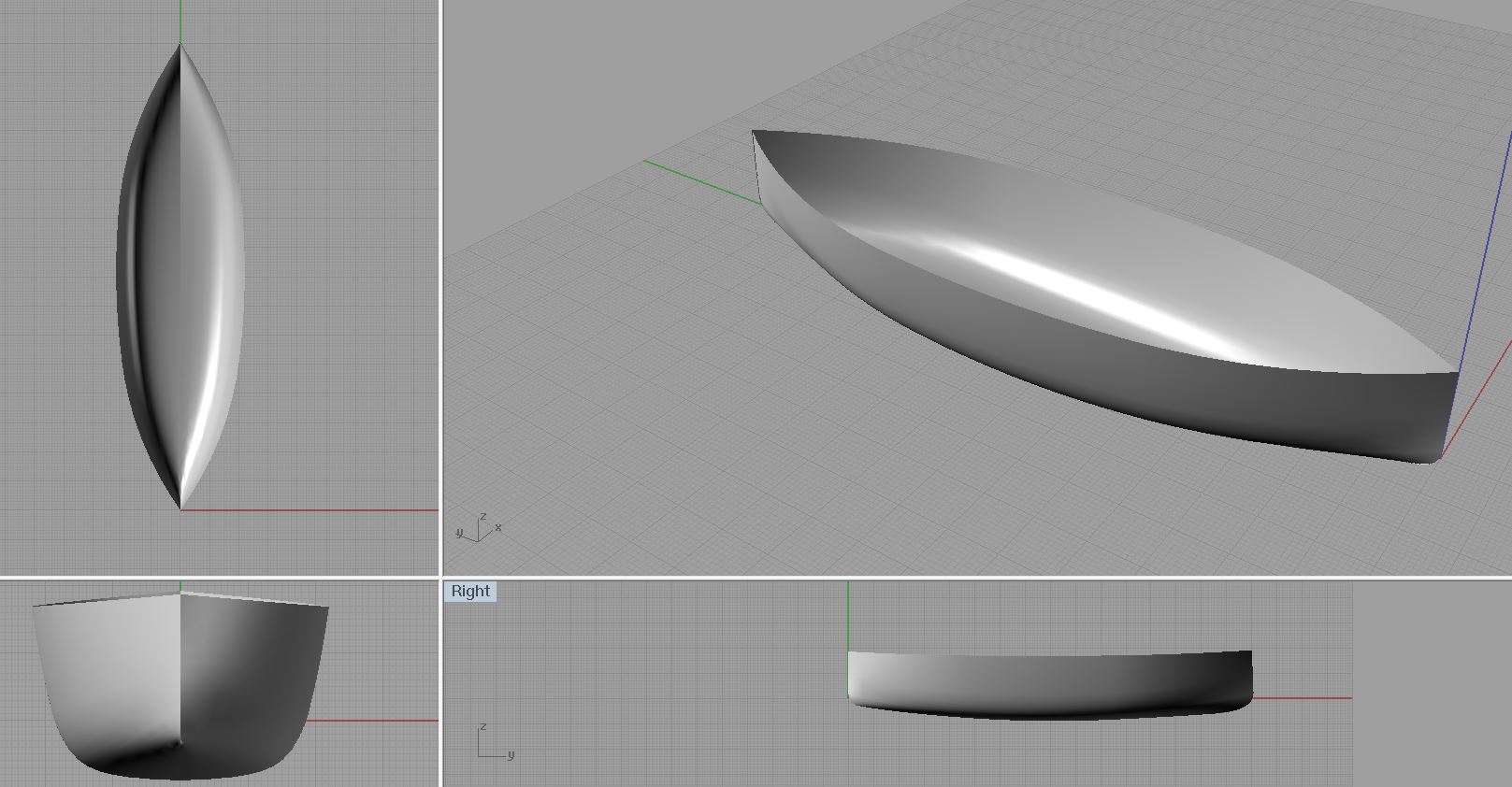

Standard Mechanical Design Software that is used for both Mechanical and Civil Engineering structural design makes a lot of sense when it comes to Structural analysis for each team, but standard hydrostatics calculations are not readily available from standard CAD like AutoCAD or similar programs. But PROLINES 8 provides not only 3D NURB hull design with unlimited shape control using 3D vertex control points that are easily adjusted to refine a “Parametric Hull Design” to initially create the first canoe design by entering basic hull dimensions in addition to bow and stern shapes selected from check boxes.

PROLINES 8 Used by more than 46 University and College Civil Engineering Teams Nationwide!

PROLINES 8 has become a design standard for Civil Engineering Student Concrete Canoe Design competitions and has been in use by CE Teams for more than 25 Years. Clearly your team should strongly consider adding PROLINES 8 to your design program. Teams across the USA will be competing against others using PROLINES for their design proposals. Don’t start your design without PROLINES 8 as one of your design tools!

Consider the following Colleges and Universities that have used PROLINES for CE Canoe Design Competitions:

Alaska, Kansas, Iowa St, Michigan St, Penn St, Purdue, Tulane, Illinois, Arkansas, Cincinnati, Central Florida, Nevada Reno, Pittsburgh, Tennessee, Texas El Paso, Utah, Washington, Wisconsin, Air Force Academy, Vanderbilt and many others!

PROLINES 8 Design Software Speeds Canoe Design

As the hull design is adjusted it becomes critical to the CE Student Team to have a detailed understanding of three critical factors. They are:

- Total Hull Surface Area – Critical to knowing the total mass of the canoe when empty and in determining the volumes of materials needed for the hull casting to determine cost of the completed canoe for the proposal.

- Stability of the Canoe with and without crew aboard. Crew weights and distribution in the canoe are easily entered in the Stability Analysis “Ballast Table”. Impact of not only crew total weight but distribution of their weight in the vessel are immediately reported in fore / aft trim calculations.

- True Loaded LWL is also determined in an instant by asking PROLINES to adjust the LWL to match the combined weight of the hull and crew. Remaining freeboard and true wetted surface calculations are now available. Even wave and friction drag calculation estimates are available to determine the value of hull shape changes.

How to Use PROLINES Hydrostatics Values for Canoe Design Trade Studies

One of the most critical real world issues the Canoe team must address is the ability of the canoe design to actually carry the required crew of 4 safely during a paddle race. The Canoe must displace sufficient water to match the combined mass of the crew and the hull itself and still have enough “freeboard” or remaining hull height above the water to prevent the canoe from swamping due to wind driven waves and splashing from spirited paddling during the race.

The Canoe Design Cycle can be imagined as follows:

- A basic Canoe shape is developed based on an initial concept.

- An estimate of the total Crew Weight is made

- Hydrostatics Calculations are run for the initial concept and the team notes:

- Computed Displacement (total weight of the boat and the crew)

- Using the Total Surface Area of the Hull and an estimate of the density of the planned “concrete” mixture per square foot, calculate the weight of the hull

- Verify the computed displacement is greater than or equal to the combined mass of the hull and crew

- If the displacement is too low, use the calculated “Pounds Per Inch Immersion” value to determine how much deeper the hull must sink before the displacement matches the hull and crew weight.

- Use the Tools Menu to “Shift the Waterline” to the desired depth and re-compute displacement

- If there is not sufficient “freeboard” remaining after the waterline is moved, make hull design changes such as flattening the hull shape below the waterline to increase displacement and slightly increase the height of the canoe sides or “freeboard”

- Overall strive to create a hull design shape that provides the lowest weight hull that can safely carry the crew. This will assure that the cost of the canoe in materials and labor will be minimized. The lowest weight canoe will also result in a faster boat and a chance to win the race as well as the design competition

- By running the design cycle repeatedly and carefully looking at hull shape, especially nearly flat hull bottoms with gently rounded sides will result in a very high “PPI” Pounds per Inch immersion factor that will allow reduced overall hull height and weight overall. Avoid a dead flat hull bottom that will generate extra drag and make the hull exceptionally hard to paddle. A slight Vee shape is desired for directional control and reduced drag when paddling. Be sure that the desired hull shape is carried through the majority of the hull length.

- PROLINES permits the design team to very rapidly close this design cycle and reduce the effort needed to create a competitive design. Values computed by PROLINES Hydrostatics and Stability Analysis functions provide extensive details for the design proposal and help assure the lowest possible cost in materials and labor.

PROLINES 8 Software Benefits Summary

Creating a Concrete Canoe Design Proposal and Submittal is a significant task. Students must have an excellent grasp of what the Canoe Design means in terms of materials and labor cost to build the canoe. The most “weight efficient” hull design will carry the weight of the crew with the lowest possible weight of the canoe hull. Not only will the lowest possible weight canoe be “weight efficient” but the lowest total mass design will be among the fastest designs on the water during the race.

PROLINES “Parametric Hull Design” offers rapid initial start to the design phase. Hull shape changes can be accomplished by simple movements of shape control vertices or overall hull changes in beam, length or draft are instantly made using the TOOLS and EDIT Menus. Saving incremental designs with serialized names will allow the team to compare design concepts by opening the various designs and choosing a most likely winner.

Standard CAD tools may offer the ability to generate a canoe hull shape but PROLINES provides integrated Analysis tools that instantly imply the viability of the design.

Once the design is complete, PROLINES 8 Student PRO edition provides 3D CAD files that permit 3D Rendering, 3D Printing, 3D Structural Analysis. For teams that are cash strapped, Vacanti Yacht Design LLC will provide one set of 3D CAD files for PROLINES 8 BASIC users at no charge to the team.

You must be logged in to post a comment.